At present, more and more industrial plants and consumers of compressed air are aware that one of the most important considerations when purchasing an air compressor is energy efficiency. Over the years of an air compressor’s life, about 75% of total operation expenses are on electricity.

Precisely for this reason, EL-AV Compressors Ltd places great emphasis on the energy efficiency of its products, and has committed itself to meeting the most stringent efficiency requirements according to international standards. In order to ensure our customers the most efficient product on the market, we have launched the EL+ Series of screw compressors.

Compressors of the EL+ Series, the most energetically efficiency today, promise a short return on investment (ROI). With a simple test, it can be seen that replacing an old compressor with an EL+ Series compressor enables a monthly return of up to thousands of usd in electricity.

By using an advanced airend and permanent magnetic motor, we ensure the customer especially high flow rates, a broad working range, especially low electricity consumption, and minimum operation costs.

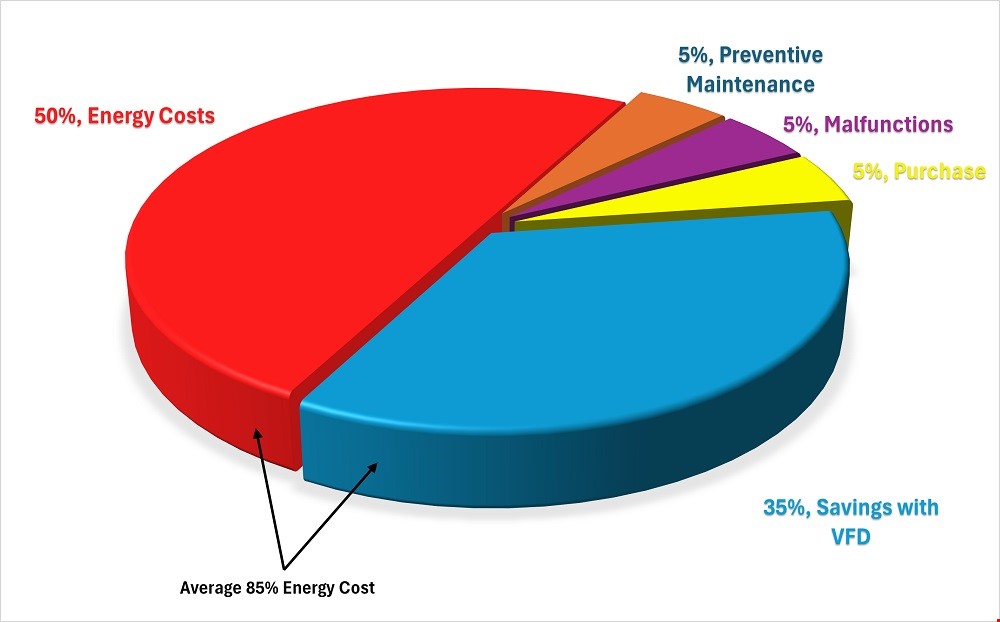

Total Lifetime Costs of an Air Compressor and Savings with Variable Speed Drives

Understanding the total cost of ownership of an air compressor is crucial for making informed decisions that can lead to significant savings over time. The total costs throughout the life of an air compressor typically include:

- Initial Investment Costs: This is the upfront expense of purchasing and installing the air compressor system.

- Energy Costs: Energy consumption often constitutes the largest portion of the total cost of ownership, sometimes accounting for up to 70% of the lifetime costs.

- Maintenance and Repair Costs: Regular maintenance and potential repairs needed to keep the compressor running efficiently.

- Operational Costs: Expenses related to day-to-day operation, including labor and potential downtime.

Savings with Variable Speed Drives (VSDs)

Incorporating a Variable Speed Drive into your air compressor system can lead to substantial savings:

- Energy Efficiency: VSDs adjust the compressor’s motor speed to match the actual demand for compressed air, reducing unnecessary energy consumption when full capacity isn't needed.

- Reduced Operational Costs: Lower energy usage translates to decreased operational expenses over the compressor's lifespan.

- Extended Equipment Life: By operating at optimal speeds, VSDs reduce wear and tear on the compressor, potentially lowering maintenance and repair costs.

Illustrative Breakdown of Costs and Savings

Standard Fixed-Speed Compressor:

- Higher energy consumption due to constant full-speed operation.

- Greater operational costs over time.

- Increased wear leading to higher maintenance expenses.

Variable Speed Drive Compressor:

- Energy consumption adjusts to demand, reducing energy costs by up to 35%.

- Lower operational and maintenance costs due to optimized performance.

- Overall reduction in total lifetime costs of ownership.

By utilizing a Variable Speed Drive, businesses can significantly decrease the total costs associated with air compressor ownership. The initial investment in a VSD-equipped compressor can be offset by the energy savings and reduced operational expenses over time.

If you’d like more detailed information or customized insights on how Variable Speed Drives can lead to savings for your specific applications, feel free to let us know!

Interested in saving electricity and operations costs in your plant? Contact us today.