EL-AV nitrogen generators are built for continuous and demanding operation. The generator is meticulously designed to achieve a single purpose - supplying available, stable, continuous nitrogen at the quality required by the customer, suitable for a very wide range of industries, each with its special requirements and customizations.

Our nitrogen systems are classified according to use in three main categories: industrial gaseous nitrogen systems, small nitrogen systems for laboratories and analytical fields, and liquid nitrogen production and bulk storage systems for cryogenic applications.

The nitrogen generators are adapted for many applications including: food and beverages, pharmaceuticals, laser cutting, electronics, textiles, plastics, universities, laboratories, and more.

The nitrogen flow rates that can be produced from the generator are virtually unlimited at 99.999% purity as standard and working pressures up to 11 bar with the possibility of enhancement up to 200 bar, with potential energy savings of up to 80% in certain models.

Using a nitrogen generator is a perfect solution for any factory looking to minimize its nitrogen costs. However, even in the field of nitrogen systems, there is room for savings in the production costs themselves through the system. By using advanced generators with upgraded CMS (Carbon Molecular Sieve), the air coefficient drops to an unprecedented ratio never offered before. This means that to produce one cubic meter of nitrogen, significantly lower air flow is required compared to other solutions available in the market.

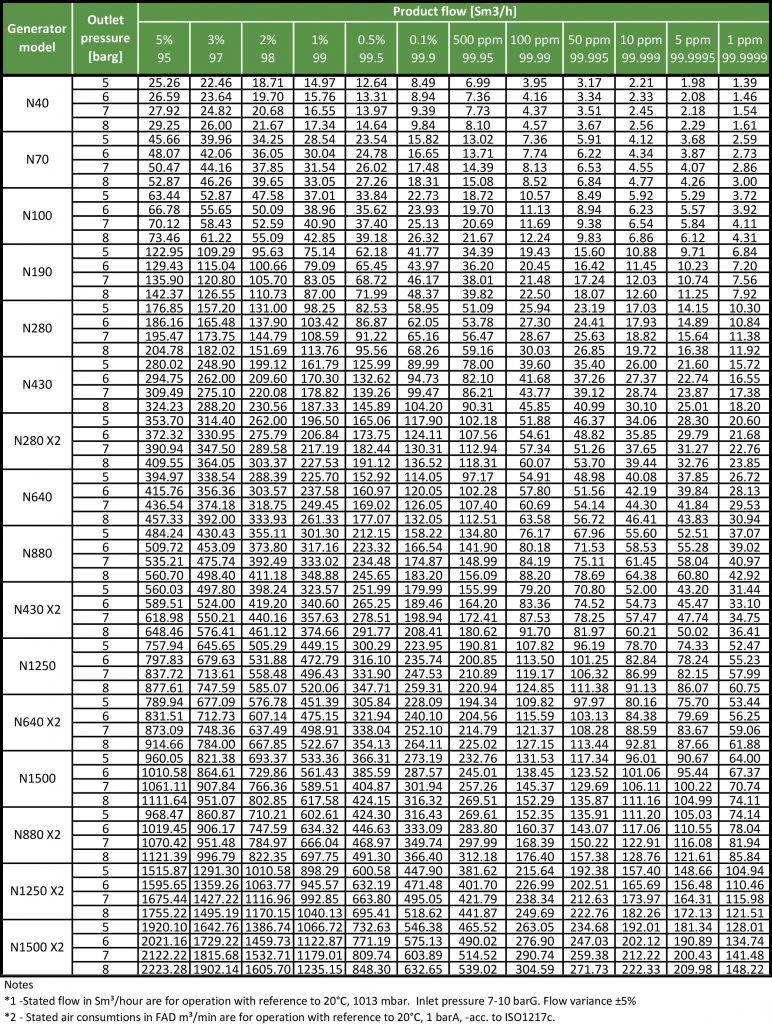

Technical Specifications

| Flow Rate |

0.11 - 5558 standard cubic meters per hour (Nm³/h) |

| Nitrogen purity |

95% - 99.9999% (according to customer requirements) |

| Working pressure |

6 - 350 bar standard (pressure can be increased upon request) |

| Dew point |

94°F |

| Ambient temperature |

41°F - 122°F |

Premium Features Standard in Our Base Models

- Intelligent control systems with advanced monitoring capabilities

- Seamless automatic operation with start/stop functionality

- Integrated nitrogen analyzer for real-time purity monitoring

- Adaptable working pressure configurations

- Premium stainless steel and copper piping components

- Extended lifespan CMS technology

- Industry-leading low air consumption and minimal pressure drop

- Robust design for continuous 24/7 operation

The systems can be enhanced with numerous upgrade options beyond the basic specifications to provide additional capabilities, such as mobile alerts via cellular communication, real-time gas monitoring sensors and instruments, automatic regeneration valves, and more. It's worth noting that nitrogen production systems are custom-tailored to each customer's specific dimensions and requirements. For example, some nitrogen systems store nitrogen in cylinders/batteries at pressures of 200 bar (atmospheres).