Oxygen generators provide an unprecedented solution for factories that continuously consume oxygen as part of their production processes.

By switching to an independent oxygen system, the factory eliminates the need to rely on third parties for supplying this essential and vital oxygen, thus beginning to produce oxygen that matches its specific needs.

Oxygen generators produce gaseous oxygen from compressed air at a low self-production cost ,providing a reliable, available, and safe alternative with significant cost savings compared to purchasing oxygen from gas manufacturers, who sell gas or liquid at prices higher by tens of percent, and requiring additional operating costs.

Oxygen Generators for Various Applications

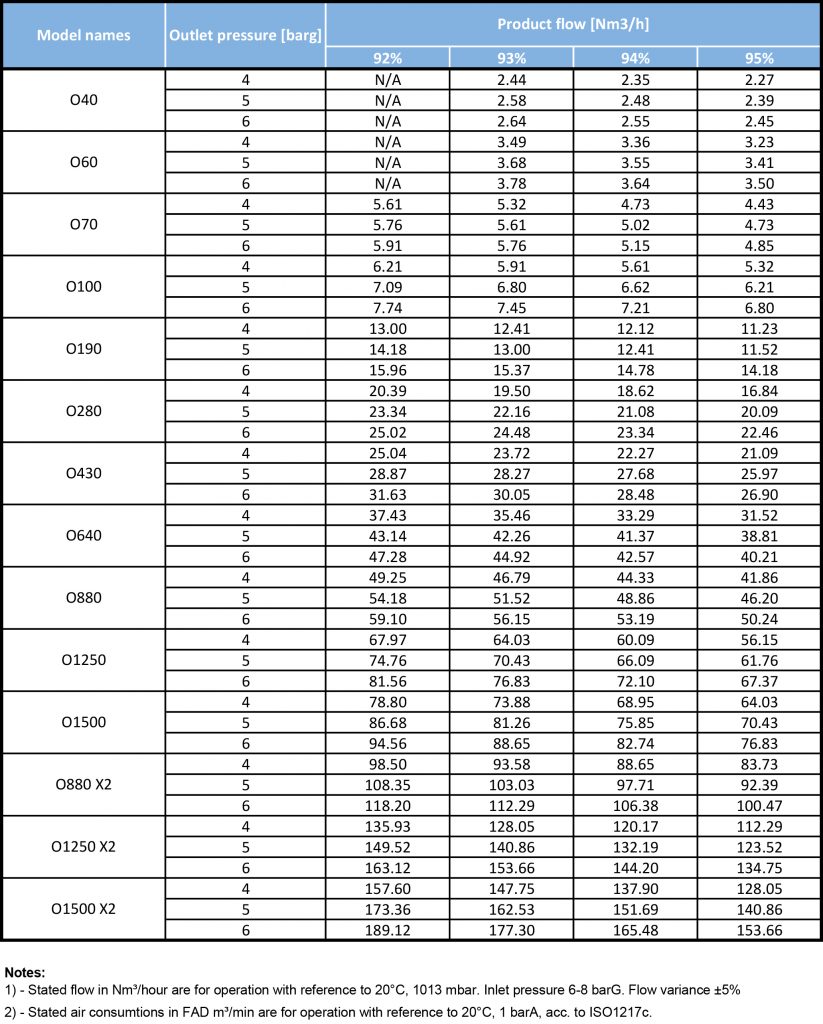

EL-AV PSA Oxygen Generators are specially designed and characterized for various applications such as: hospitals and medicine, laboratories, industry, and more, with different flow rates between approximately 0.1 to 473 standard cubic meters per hour (Nm³/h) with purity of up to 95%. Our oxygen generators are manufactured at the highest quality and level available, both in materials quality and in the smart control system that manages their operation in the most efficient way. This high quality allows the generators to work under full load 24/7, providing customers with industrial peace of mind for years.

Our PSA Oxygen Generators work using Pressure Swing Adsorption (PSA) technology, which is the most common and efficient among gaseous oxygen generators. The process occurs through two columns filled with zeolite, which is a molecular adsorbent/filter material. The treated compressed air flows through one of the columns in each cycle. Nitrogen and other gases are captured while oxygen continues to flow freely. When the active column becomes saturated, the air is directed to the second column while simultaneously the residual gas (nitrogen and other non-oxygen gases) is released into the atmosphere until the column is completely refreshed and purified.

The process continues cyclically, with one column producing oxygen while the second regenerates, and at the end of each cycle, the columns switch functions. The generator produces a constant flow of oxygen with purity of up to 95%.

Our customers enjoy high standards from the basic models such as:

- Smart control

- Communication - remote control and monitoring

- Automatic stop and start

- Built-in particularly durable paramagnetic/zirconium oxygen analyzer

- Flexibility in working pressures

- Stainless steel/copper pipes

- Zeolite with especially long lifespan

- Among the lowest compressed air consumption and pressure drops available

- Heavy duty generators for intensive 24/7 operation

Our generators meet all the most stringent requirements and standards such as:

- ISO9001:2015

- ISO13485:2016

- ISO14001:2015

- PED 97/23/EC Module B+D

- MDD 93/42/EEC

Technical Specifications

| Flow rate per unit |

0.1 - 473 standard cubic meters per hour (Nm³/h) |

| Oxygen purity |

90% - 95% (according to customer requirements) |

| Working pressure |

4 - 6 bar |

| Dew point |

<-58°F (less than 67 PPM) |

| Ambient temperature |

41°F - 113°F |

*Possible to reach pressure of up to 200 bar for cylinder/battery filling

Many components can be upgraded to provide the generator with additional capabilities, for example, cellular communication for real-time alerts to mobile phones, sensors and measuring equipment for real-time gas monitoring, automatic refresh valves, and more.

It is important to note that oxygen production systems are customized to the dimensions and needs of the customer and are manufactured for each customer according to their requirements.