The EL+ Variable Speed Screw Compressor Series, a Demand-Driven Approach

In industrial compressed air systems, energy costs represent the largest share of long-term operating expenses.

As electricity prices continue to rise, managing these costs has become an operational priority that directly impacts profitability, reliability, and long-term planning.

Effective cost management does not start with individual components or headline efficiency claims. It begins with a structured, demand-driven framework that aligns compressed air production with real operational needs and focuses on how the system behaves over time.

This article outlines a practical approach to managing compressed air energy costs, with an emphasis on execution rather than theory.

The EL+ Variable Speed Screw Compressor Series is referenced as a real-world implementation of this framework, illustrating how demand-based control and intelligent system design can translate into measurable, long-term savings.

Understanding Where Energy Costs Accumulate Over Time

In most industrial environments, compressed air demand is inherently variable. Production schedules change, equipment cycles fluctuate, and air consumption rarely remains constant throughout the day or across shifts.

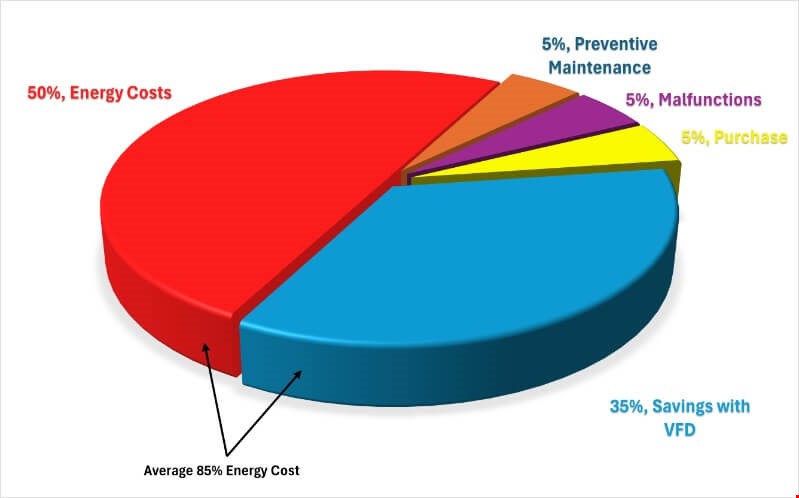

Under these conditions, electricity becomes the dominant cost factor over the life of a compressor. In many installations, energy expenses outweigh the initial capital investment several times over, making total cost of ownership a far more meaningful metric than purchase price alone.

A practical energy cost framework therefore considers questions such as:

- How closely does air production follow actual demand.

- How much time does the system operate unloaded or inefficiently.

- How are demand fluctuations managed throughout the day.

- How quickly are inefficiencies identified and addressed.

Demand-Driven Compression as the Foundation of Cost Control

Traditional fixed-speed compressors are designed to operate at constant output, regardless of real-time demand. When consumption drops, energy is often wasted through unloading cycles, idle operation, or repeated start-stop sequences.

A demand-driven compression strategy addresses this mismatch by continuously adjusting output to match actual air requirements. Variable speed control allows energy efficient inverter screw compressors to operate across a wide load range, increasing or decreasing capacity in response to changing demand.

Illustrative comparison of energy behavior under variable demand conditions:

In practical applications, this approach has demonstrated substantial impact. Demand-driven systems have shown average reductions of up to 50 percent in electricity consumption compared to conventional fixed-speed operation, depending on system size, operating profile, and demand variability.

Beyond energy savings, this strategy delivers additional operational benefits:

- Reduced idle and unloaded operation

- Lower inrush currents during startup

- Less mechanical stress on components

- More stable system pressure

- Improved long-term reliability

The EL+ Variable Speed Screw Compressor Series applies these principles by combining variable speed control with a system architecture designed for continuous adaptation to real operating conditions.

High-Efficiency Drive Technology Under Variable Loads

Matching output to demand is only effective if the drive system itself maintains high efficiency under partial and variable loads. In real industrial environments, compressors rarely operate at full capacity for extended periods.

Permanent magnet motor technology at IE4 Super Premium efficiency levels plays a key role in this context. When paired with advanced speed control, these motors sustain high efficiency across a broad operating range rather than only at nominal load.

This contributes to:

- Improved efficiency during partial-load operation

- Reduced electrical losses during speed modulation

- More consistent performance under fluctuating demand

In long-term operation, these characteristics support meaningful reductions in total energy consumption and contribute directly to lower total cost of ownership.

Monitoring, Visibility, and the Cost of Undetected Waste

Even well-designed compressed air systems can become inefficient if consumption patterns are not actively monitored. Air leaks, pressure deviations, and other hidden sources of waste often go unnoticed while steadily increasing energy costs.

A robust energy cost management framework therefore includes continuous monitoring and intelligent control. By tracking air consumption and identifying abnormal deviations, operators gain visibility into inefficiencies that would otherwise remain hidden.

This visibility enables facilities to:

- Detect leaks and losses earlier

- Prevent gradual increases in energy usage

- Maintain stable and predictable system performance

- Support data-driven maintenance and optimization decisions

In practice, this level of control plays a significant role in sustaining energy savings over time rather than achieving one-time improvements.

From Energy Efficiency Claims to Measurable Outcomes

Discussions around compressed air often focus on energy efficiency as a general concept. While important, efficiency only delivers value when it is translated into consistent operational behavior.

A demand-driven framework shifts the focus from claims to outcomes. It emphasizes how compressors respond to real demand, how energy use is controlled throughout the operating range, and how performance is maintained year after year.

In real-world deployments, systems built around these principles have demonstrated not only significant energy reductions, but also measurable improvements in total cost of ownership. Over a typical operating horizon of around 10 years, reductions of approximately 36 percent in total cost of ownership have been observed, reflecting lower energy consumption, reduced wear, and improved system stability.

Within this context, the EL+ Variable Speed Screw Compressor Series serves as a practical example of how demand-driven design can be applied in industrial compressed air systems.

Final Thoughts

Managing compressed air energy costs is not about a single technology or feature. It is about aligning production with demand, maintaining efficiency under variable operating conditions, and continuously monitoring system performance to prevent waste.

A structured, demand-driven framework provides a practical path toward achieving these goals. When applied consistently, it turns compressed air from a hidden and unpredictable expense into a controllable operational asset with measurable financial impact.

Want to know how much you can save?

Contact us and our team will be happy to help you evaluate your compressed air system, understand its operating profile, and assess the potential cost reductions achievable with a demand-driven approach.