EL-AV introduces the BL Series two-stage piston compressors - a new standard in heavy-duty reliability and performance. Explore how it's standing apart.

BL Series: Built for Industry, Engineered for Endurance

EL-AV introduces the BL Series two-stage piston compressors - a new standard in heavy-duty reliability and performance. With a cast-iron pump, UL-certified components, integrated after-cooling, and ASME-approved tanks, the BL Series is built for industry professionals who demand efficiency, endurance, and clean compressed air without compromise.

When it comes to compressed air, reliability is everything. From factory floors to auto shops, every operation depends on air power that works as hard as its people. That’s where the new BL Series two-stage piston compressors from EL-AV take the spotlight - combining classic heavy-duty design with advanced cooling technology for performance that simply doesn’t quit.

Heavy-Duty Engineering for Demanding Work

Every detail in the BL Series is designed to last. At its core is a two-stage solid cast-iron pump - the heart of a compressor built for industrial duty. This heavy-duty construction ensures superior strength, minimal vibration, and exceptional heat resistance. Unlike lighter single-stage models, the BL Series operates at low RPM, reducing wear and extending component life.

Inside the pump, dual solid-steel connecting rods and industrial-grade removable disc valves make maintenance straightforward while ensuring consistent performance under continuous load. Oversized bearings, precision-balanced crankshafts, and stainless-steel valves all contribute to smooth operation and long service intervals.

This robust foundation means one thing: reliability you can count on shift after shift, even in the harshest environments.

a two-stage solid cast-iron pump

Certified Quality and Safety

Industrial reliability starts with compliance. Every BL Series compressor is assembled from UL-certified components and mounted on an ASME-certified air receiver - a clear mark of quality and adherence to international safety standards.

Available in 60, 80, or 120-gallon configurations, each tank is equipped with vibration-isolation pads that minimize noise and structural stress. The system also features an automatic dual-timer tank drain, removing accumulated water automatically and reducing maintenance needs.

It’s this level of engineering detail - down to the last bolt - that defines EL-AV’s commitment to building equipment you can trust.

Cooler Air. Drier Air. Smarter Design.

Traditional piston compressors are notorious for producing high discharge temperatures, which make it difficult to remove moisture from the air stream. Hot air carries more water vapor, leading to condensation downstream and the need for costly high-temperature dryers.

The BL Series changes that equation. Each unit integrates an advanced aluminum intercooler and after-cooler system, along with an auto-drainer, which together reduce the air temperature dramatically before it leaves the compressor.

This built-in cooling system offers a double advantage:

- It improves air quality by reducing moisture content at the source.

- It often eliminates the need for a high-temperature dryer - and in some installations, no dryer is needed at all.

When a dryer is required, a standard dryer will usually suffice, saving both cost and space. The result is cleaner, drier, and cooler compressed air that protects tools, equipment, and processes.

How the BL Series Piston Compressors Stand Apart

Most piston compressors on the market still follow older design principles - limited cooling capacity, higher discharge temperatures, and greater moisture buildup that shorten component life and demand expensive high-temperature dryers.

The BL Series breaks that pattern with its integrated aluminum after-cooler and auto-drainer system, delivering cooler, drier air and protecting internal components from thermal stress. It’s an industrial-grade piston compressor engineered with the efficiency of modern rotary systems, giving users the best of both worlds: rugged mechanical strength and advanced cooling innovation.

Performance That Pays Off

Energy efficiency is built into every part of the BL Series. Optimized cylinder geometry and precision engineering deliver more CFM per horsepower, translating to higher air output with lower energy consumption.

A premium-efficiency NEMA motor - available in single-phase or three-phase versions - provides reliable power and consistent performance under continuous duty. The system’s independent magnetic motor starter includes under-voltage and overload protection, preventing damage and extending motor life.

All these features work together to minimize operating costs and ensure stable, uninterrupted production.

Easy Maintenance, Long Life

Downtime costs money, so the BL Series is designed for effortless upkeep. Individual cast cylinders and accessible valve pockets simplify service tasks, while long-life piston rings and high-grade materials reduce replacement frequency.

The automatic 110-volt dual-timer drain eliminates the hassle of manual tank drainage, while fully enclosed heavy-duty belt guards protect operators and help cool the drive system. With fewer manual tasks and simplified maintenance routines, your team can focus on production instead of repairs.

Adaptable by Design

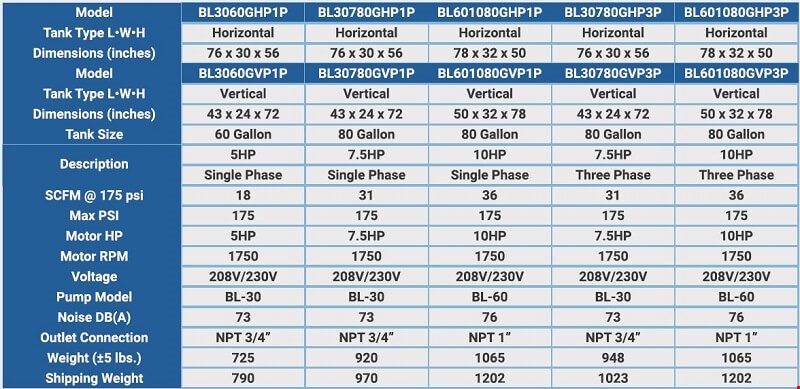

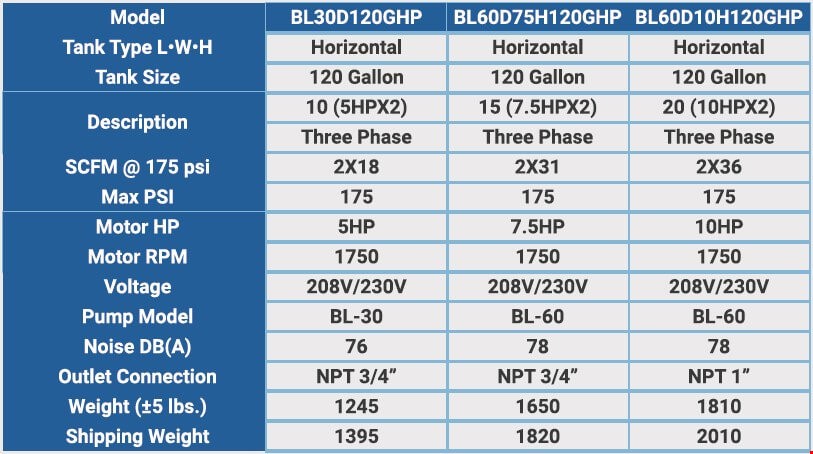

No two facilities are identical - and neither are their compressed air demands. That’s why the BL Series offers flexible configurations:

- Vertical or horizontal tank layouts for space optimization.

- Duplex systems for redundancy or alternating load sharing.

- Compatibility with dryers, filters, drains, and smart control modules, letting you tailor the system precisely to your workflow.

Whether it’s a small machine shop, a lab, or a full-scale industrial line, there’s a BL model to fit your needs:

Protecting Your Investment

Large intercoolers and after-coolers provide efficient heat dissipation, protecting pistons, valves, and seals from excessive thermal stress. Additional built-in safeguards - like low-oil protection and overload prevention - further enhance system longevity.

These features extend the compressor’s operating life, reduce maintenance costs, and deliver long-term return on investment. It’s not just about performance on day one - it’s about reliable performance for years to come.

Final Thoughts

Compressed air doesn’t have to be the silent budget drain in your facility. By combining robust cast-iron durability with advanced cooling technology, the BL Series piston air compressors deliver reliability, efficiency, and clean air that stand apart from conventional piston designs.

The BL Series embodies EL-AV’s commitment to designing compressors that merge industrial strength with smart engineering - built for performance, built for industry.

For further information, please feel free to contact us >>

This might also interest you:

The Hidden Cost of Compressed Air: 10 Energy-Saving Secrets